NTSCGEWOEU

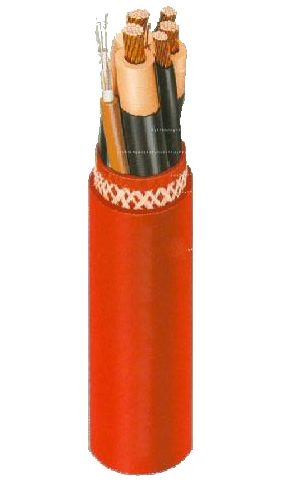

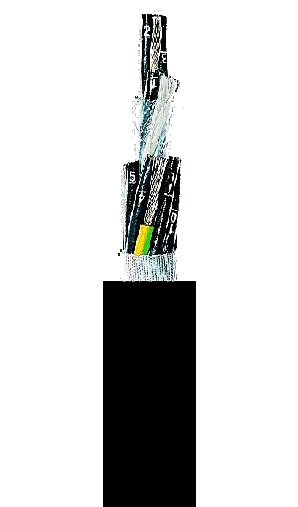

Cable construction

- Standards according to DIN VDE 0250

- Electrolytic copper, not tinned, very finely stranded, Class “FS”

- Basic material EPR, compound

- Electrical field control consists of inner and outer semi-conductive layer of semi-conductive rubber

- Core identification natural colouring with black semi-conductive rubber on which white digits 1 to 3 are printed

- Core arrangement with three main conductors laid-up, with protective-earth conductor split into three in the outer interstices

- Inner sheath: basic material EPR compound

- Anti-torsion braid of polyester threads in a vulcanized bond between inner and outer sheath

- Outer sheath: basic material PCP, colour red

- Rated voltage: Uo/U = 3,6/6kV to 18/30kV

- Max. permissible operating voltage in A.C systems: Uo/U = 4,2/7kV to 20,8/36kV

- Max. permissible operating voltage in D.C systems: Uo/u = 5,4/10,8kV to 27/54kV

- A.C test voltage: 11kV to 43kV according to DIN VDE 0205

- Current-carrying capacity according to DIN VDE 0298

- Ambient temperature

- Fully flexible operation: -25°C to +60°C

- Fixed installation : -40°C to +80°C

- Max permissible operating temperature of conductor: 90°C

- Short circuit temperature of conductor: 250°C

- Tensile load: up tp 20N/mm²

- Torsional stresses: +100°/m

- Min. bending radii according to DIN VDE 0298

- Min. distance with S-type directional changes: 20 x Ø

- Travel speed

- In operation: up to 60m/min

- On rewinding: 100m/min

For connection of large material handling machines such as excavators, dumpers, mobile crushes in open-cast mines. Flexible MV reeling cable suitable for high mechanical stresses in conjunction with mono spiral reels and cylindrical reels.