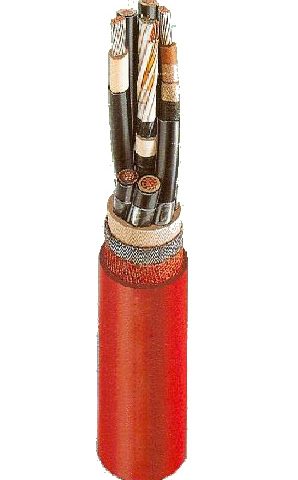

NSSHCGEOU

Cable construction

- Finely stranded copper conductor, tinned, class 5.

- Productive-earth conductor: overall concentric steel/copper wire spinning

- Control core: double concentric control/monitoring conductor elements in the center element

- Insulation basic material EPR, compound

- Outer semi-conductive cold strippable rubber

- Cores arranged three or six main cores laid-up, with double-concentric control/monitoring conductor elements in the outer interstice: length of approximately 6 x Ø

- Closed lay spinning of steel/copper wires in a vulcanized bond between inner and outer sheath

- Resistance to oil according to DIN VDE 0473

- Behaviour in case of fire to DIN VDE 0482

- Weather resistant

- Core colours: Main cores black, blue, brown Control cores blue

- Inner sheath vulcanized rubber sheath, base material EPR

- Outer sheath PCP-special compound yellow or red

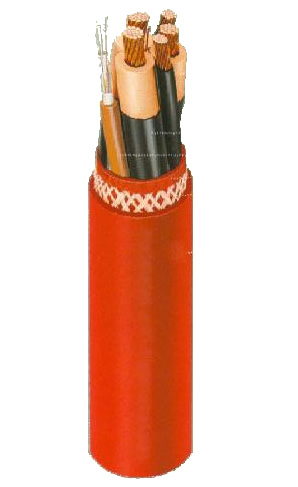

- As per DIN VDE 0250

- Temperature range

- Flexing: -20°C up to + 60°C

- Fixed installation: -40°C up to +80°C

- Nominal voltage: Uo/U = 0,6/1kV, 1,8/3kV, 3,6/6kV

- Test voltage: Power cores 3kV, 6kV, 11kV Control cores 2kV

- Minimum bending radius as per DIN VDE 0298, or 2,3 x diameter at max. 5N/mm² tensile strength

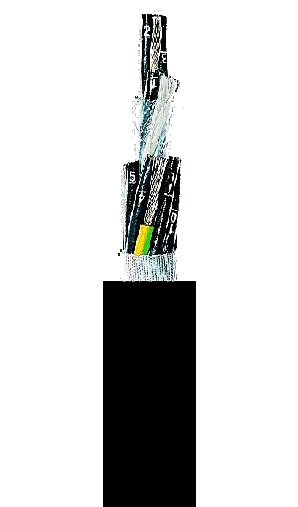

Used as power supply connection cable for mobile equipment and machines in underground mining applications, such as coal cutting machines. These cables are designed for use in cable protection chains, which are trailed behind the machine and which absorb the thereby occurring tensile forces.